Get Existing Conditions With 3D Laser Scanning Reality Capture

With a team of professional surveyors and USIBD certified professionals, TrueScan provides 3D laser scanning services that help you document your room, building, or structure efficiently and accurately.

We proudly cover all regions of the United States – serving cities like Chicago, Miami, Atlanta, Washington D.C. and many more – by delivering existing conditions straight to your desk.

Instead of working with outdated building plans or field measurements, with 3D blueprints CAD drawings all of your designs are based on true-to-life measurements and existing conditions.

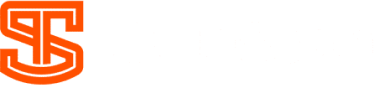

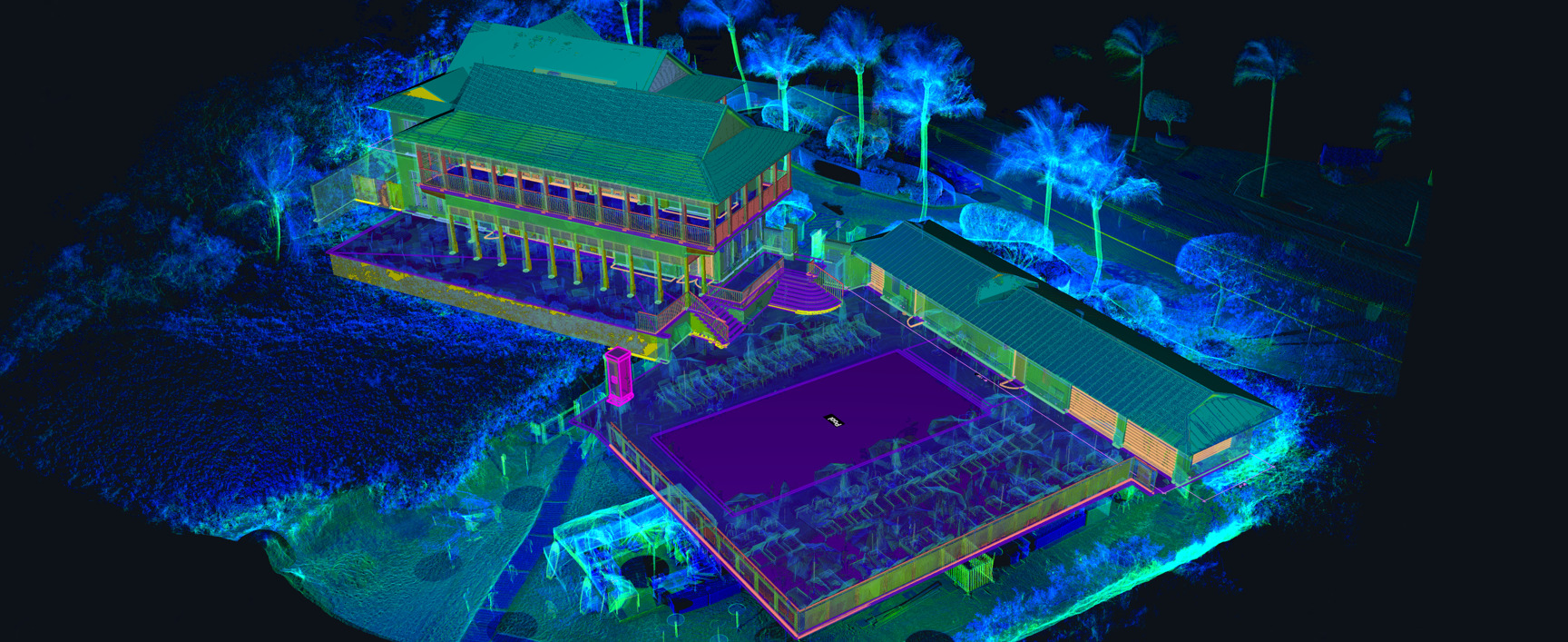

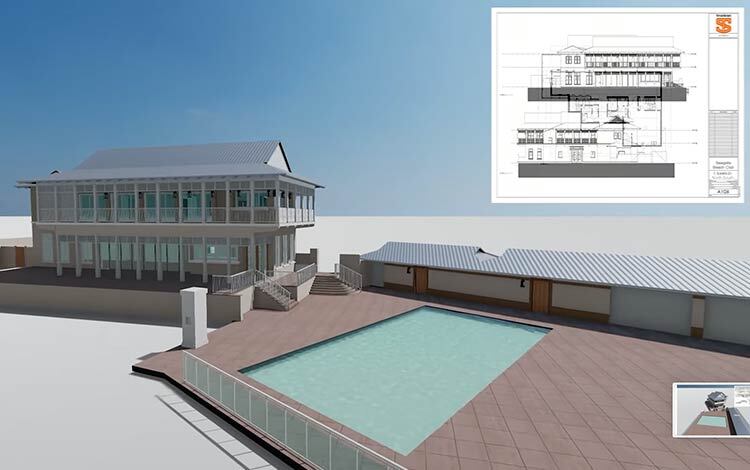

3D Laser Scanning of Seagate Beach Resort

Your Project’s Journey from 3D Scanner to Reality

Average Price

$4,000-$12,000+

Prices vary based on many factors, read more about the factors that go into the price of your laser scanning service or get a quote today.

Average Timeline

2 – 6 weeks

With more precise details on the needs of your project, we can nail down an expected price and timeline.

Deliverables

At the completion of this service, you’ll receive a full digital map of your building that you can explore inside and out. Based on your company’s needs, we can either turn your scan into a fully comprehensive digital model or turn a complete point cloud over to you.

Benefits

- Fast & Reliable

- Discover Unknowns

- Reduce Change Orders

- Accelerate Your Project