What is TrueScan’s Method?

When it comes to information like floor flatness, we at TrueScan want to make sure our clients have every bit of information they need to know more, risk less, and build better. When working to build better, it is vital to have information on hand during all project points. While having some data is good, you need definitive and trusted information when assessing flatness and levelness for a structured foundation. The process begins with our team of experienced surveyors and scanning professionals evaluating your needs and understanding the various essential elements of your project. Once we have this knowledge, we come to your site and use our 3D laser scanning technology to provide you with the most exact floor flatness data possible.

To accurately assess floor flatness and levelness and give a detailed recommendation, TrueScan will establish a datum level. Establishing a datum level can be done in one of two ways, but it is best to have both:

Establish Survey Control

To find proper floor flatness, TrueScan will establish survey control. Luckily, our team includes multiple licensed surveyors who quickly provide this service on-site without extra hands or equipment.

Scanner with a Dual-Axis Compensator*

Unlike some of our competitors, TrueScan works with scanners that have this capability. TrueScan’s scanners also have an advanced leveling system that locks each scan to its own datum level, allowing for 3 degrees of freedom on every scan. This leveling system prevents the scanner from tilting, moving, and negatively affecting the data during the registration process. You can trust TrueScan’s services and experienced technicians to quickly provide your team with the most exact floor flatness data possible.

* You should note that not all 3D laser scanners are created equally, and not all firms with scanners include this capability.

Assessing the Risk: What Happens if My Floor Isn’t Flat or Level?

Although it may be a common misconception, flat does not necessarily mean level, and level does not always mean flat. A floor can be one without the other. But to be successful, a foundation needs to be both flat and level. So, what happens if this isn’t the case? It’s essential to know the possible risks:

Structural Issues

One of the most critical issues that can arise if a floor isn’t flat or level is structural. A base floor that is a few degrees off level or has waves and creases can cause longstanding problems with the structure the more it is used.

Operational Issues

Aside from structural issues, an uneven floor can easily cause operational problems. A foundation that has ridges, waves, or other level and flatness issues significantly affect functional capacity. For companies like Amazon, floor flatness and levelness are of the utmost importance. Amazon’s Scout robots in their smart warehouses rely on precise floor markers to direct them around the warehouse as they move shipments. Waves, dents, or wrongly sloped areas can cause malfunctions with the robots and throw the production of the entire warehouse off. Similarly, these same issues could cause workers in heavy machinery like forklifts to crash or break down while in operation. Operational problems can cause loss of product, revenue, time, or all three.

Safety Issues

Companies need to ensure their workers are physically safe as they carry out their daily tasks and routines. A floor with flatness or level issues can inadvertently cause bodily harm to employees before they even realize the accident is about to happen. Workers can be hurt by crashes or malfunctions of operational equipment, falling shelving or product, or other dangerous scenarios. These issues could cause halts in productivity, costly equipment repairs, product loss, or, even worse, employee injuries or casualties.

Although many of these scenarios are consequences of extreme issues, the possibility still exists. These issues are also not specific to manufacturing organizations – no one is safe from a warped floor! Luckily, TrueScan and 3D laser scanning can alleviate these issues.

How Can TrueScan Help?

As we’ve mentioned above, traditional methods only cover what the human eye can see. 3D laser scanning examines the minute details and shows you your building or space in a way you’ve never seen before. Our team makes sure you know every detail about your space before you begin.

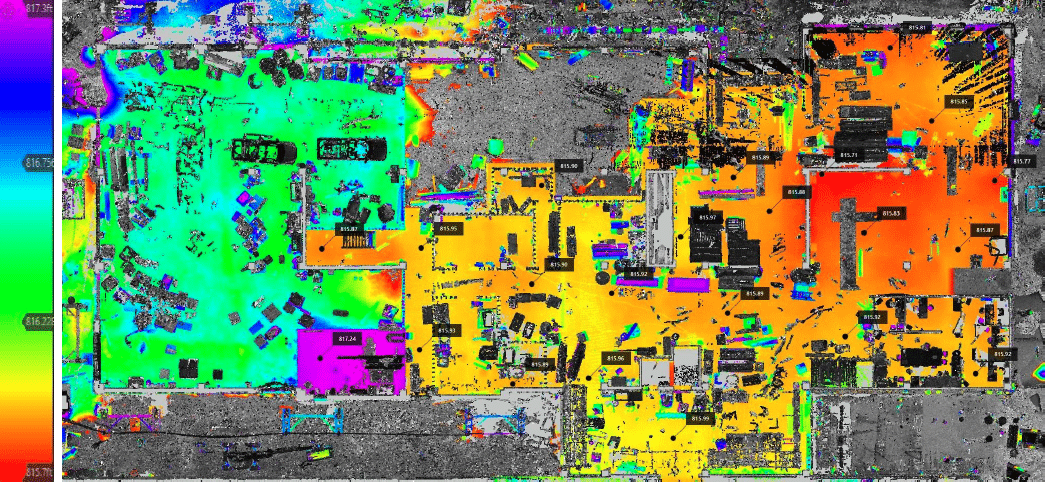

Unlike traditional methods, TrueScan provides you and your team with comprehensive data that is easy to digest and review. After performing the flatness test, TrueScan gives you an incredibly detailed heatmap that shows the change in flatness level across the entire space. This heatmap is delivered in full color and is readily discernible for all stakeholders involved. An added benefit of the heatmap is pulling measurements directly from any point on the map. Need to know the specific flatness and level at an obscure point in the building? TrueScan’s heatmap makes that information readily available.

From that data, TrueScan supplies a precise contour map that shows you and your team the various elevations of the floor across the entire space. This map takes out the need for any speculation or hand-checking to make sure the elevations are documented. Now, stakeholders can review one map and know precisely how elevation changes will affect their entire structure.

On top of the heatmap and contour map, TrueScan also supplies an inclusive cut & fill analysis of the area. This analysis allows AEC team members to see what flooring areas need to be cut or have flooring added to reach optimal flatness and level. The cut & fill helps TrueScan clients accurately decide how much material is needed, preventing unnecessary change orders and production costs. The Project Analysis Group found that an average of 35% of all construction projects will have a significant change. With a cut & fill analysis from TrueScan, you and your team can easily avoid these critical changes.

Invest in TrueScan Today

TrueScan wants you and your team to work with the best possible data in the most efficient ways, whether it’s on floor flatness, spatial analysis, or other building needs. No one likes change orders or projects derailing, and in the new world of AEC, production needs to be as efficient and cost-effective as possible. TrueScan makes all this possible and can work with any building project, no matter the size or distance. Work with a trusted provider and reliable data to make your dream project a reality. Call TrueScan today.

Get a Free Quote

"*" indicates required fields

Get a Free Quote

"*" indicates required fields