Parking Garage Scanning

Columbus, OH

Parking Garage Scanning

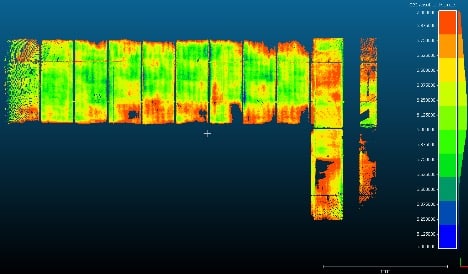

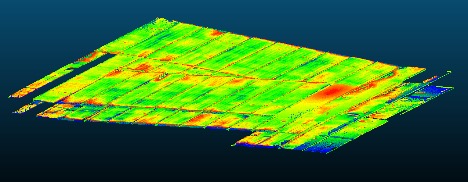

TrueScan was retained by a large general contractor to provide 3D laser scanning services to scan three stories of a parking garage in Columbus, Ohio. The goal of the project was to measure the slab thickness of the sloped ramps contained within the garage. Using the point cloud that was generated from the field scanning, TrueScan engineers generated a report consisting of heat maps for each ramp section to display slab thickness.

The parking garage was scanned so that the bottom and top of the slab would be fully captured. The resulting point cloud was then separated into two separate point clouds (top of slab and bottom of slab). Using the software, Cloud Compare, the scans were then used to create a surface deviation color map. The result was a heat map showing the deviations of the top of the slab from the bottom of the slab. Due to the slabs being sloped, the deviations reported were based on the surface normal (perpendicular to the slab surface and not the z-direction). This showed the true thickness of the slab.

Before contracting TrueScan, the contractor tried other approaches to capture the existing information, including using an inverted rod and collecting data using the traditional survey approach. Due to the slab being sloped, this method proved to be difficult to capture the true thickness of the slab. Using 3D laser scanning technology, TrueScan was able to provide the contractor with the information that couldn’t be achieved traditionally, in a fraction of the time.

Get a Free Quote

"*" indicates required fields

Get a Free Quote

"*" indicates required fields